Timing belts

Positive traction drives

A positive traction drive guarantees a synchronous transmission between the pulleys – therefore, it is also called synchronous drive. This kind of power transmission is gaining further importance due to its very high-power ratings and striking life cycles.

Angst+Pfister’s timing belts meet our customers’ highest demands and can be adapted to any application in accordance with the construction specifications and deployment conditions.

Elastomer or polyurethane?

Timing belts are available in different materials, but the most common ones are made of elastomer or polyurethane. Elastomer is used as a general term for polychloroprene as well as any related elastomer compounds. The same applies to polyurethane, as different compounds from polyether or polyester are available, which are suitable for casting or extruding manufacturing processes. The commonly used abbreviation TPU stands for thermoplastic polyurethane. Before selecting from the two materials, elastomer or polyurethane, parameters like purpose, requirements and the environment should be defined, since all these parameters can also have an impact on the reinforced tension member, which can be made of steel, glass, aramid or carbon.

The perfect belt solution for each application

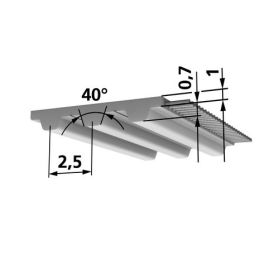

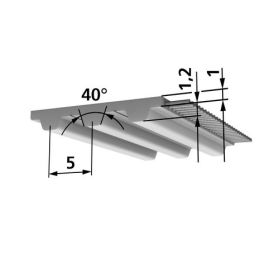

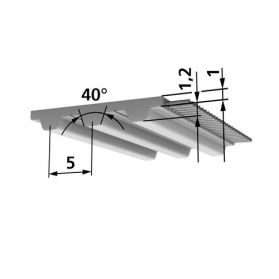

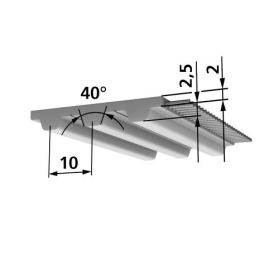

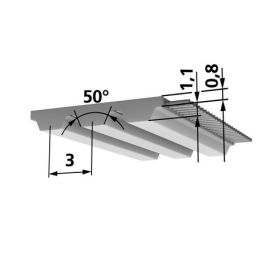

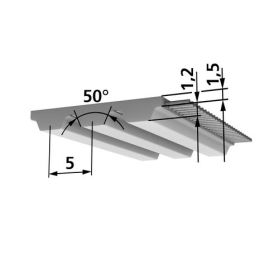

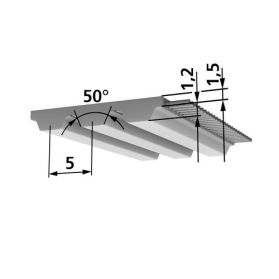

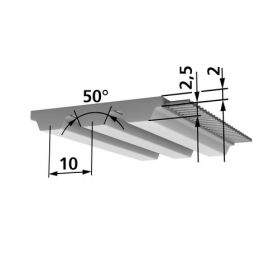

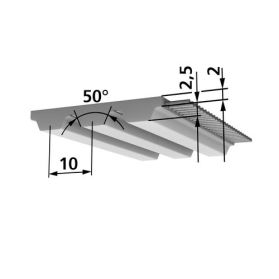

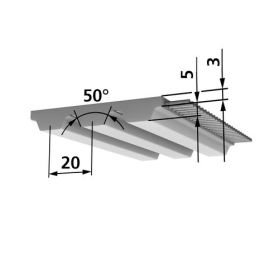

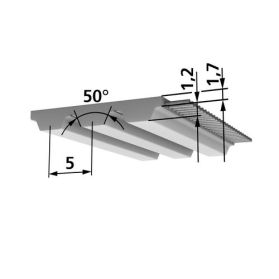

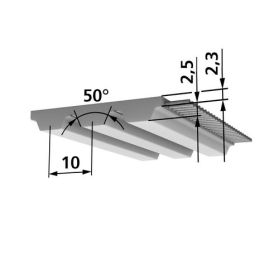

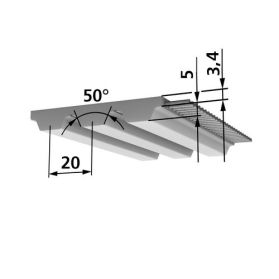

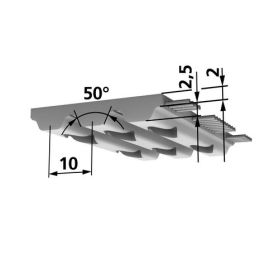

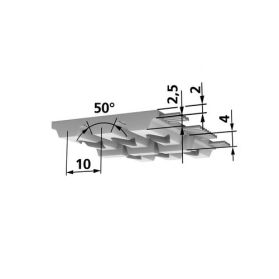

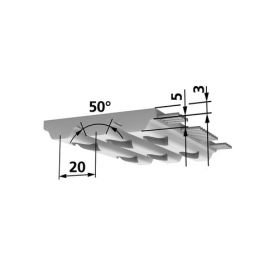

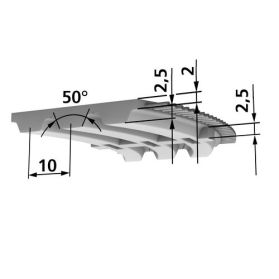

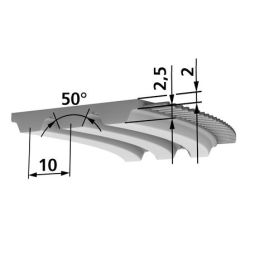

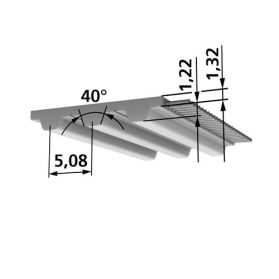

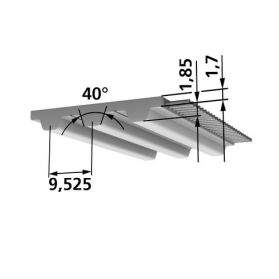

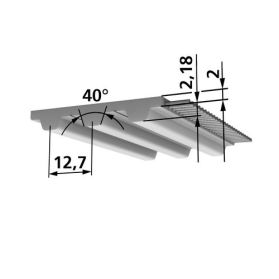

Whether made of polyurethane or rubber, a variety of tooth profiles and pitches have been specially designed to meet the most demanding requirements in industrial applications. No matter how complex your application is, our engineering team will help you to configure the right timing belt in order to provide you with the best solution.

Endless timing belts for power transmission applications individually manufactured tooth by tooth

• Manufactured in endless lengths without interruption of the tension members

• Can be operated both in continuous operation and in start/stop operation

• Available in standard and intermediate lengths up to 30’000 mm

Timing belts by meter for linear transmission applications

• Manufactured as open length belts

• Used in applications such as industrial robots, racking systems, cutting and drawing plotters and in handling systems

• Suitable for high accuracy positioning and smooth movements in all directions

Welded timing belts for conveying applications

• Made from open length polyurethane timing belts

• Achieve at least 50% of the permissible tensile force of endless belts

• Can be welded in any specified length

Rubber timing belts

• Broad range of rubber timing belts made of chloroprene with glass fibre tension cord, shear strength teeth and running surface protective fabric

• High performance specificaions to meet the strict requirements of extremely demanding drives

• Maintenance-free