Drive Technology

A full range of high-quality and innovative mechanical drive technology products

Angst+Pfister has a leading heritage of technical evolution and innovation. As engineering experts in drive technology components, we strive to provide our customers with innovative design parts to improve performance, increase efficiency and decrease costs.

Selecting the correct materials, components and configurations is a complex and time-consuming process, but crucial for the success of a drive system. APSOparts makes this process easier for you – with smart filter functions and all relevant technical data, you can find your ideal solution quickly and easily.

Thanks to its excellent functionality, belt drives are used in stationary industrial applications, in automated robotic processes and in transport and materials handling technology, especially within the packaging, food & beverage, pharmaceutical, wood and metal processing industry.

Starting with timing belts, V-belts and the associated pulleys all the way to couplings, shaft locking devices and the corresponding accessories, our APSOparts online shop offers you the entire Angst+Pfister standard range within the mechanical drive technology.

Traction drive

Traction drives, or commonly known as belt and chain drives, are generally used to transmit power or motion. A traction drive can also be used to move or position items, which is commonly known as transport or linear technology. Subject to the task an application has to achieve, there are several possibilities to complete the challenge. Traction drives are divided into two categories: the positive traction drives for timing belts or chains and friction traction drives for V-shaped belts, as well as round and flat belts.

Positive traction drives

A positive traction drive guarantees a synchronous transmission between the pulleys – therefore, it is also called synchronous drive. This kind of power transmission is gaining further importance due to its very high-power ratings and striking life cycles.

Friction traction drives

Compared to positive traction drives, friction traction drives have the significant advantage of tolerating a temporary slippage due to excessive overload. It is the nature of this kind of traction-drives that higher pre-tension forces have to be applied to ensure a flawless operation. Also, the belt is subject to constant slippage, as a result of which a perfect synchronous transmission cannot be achieved.

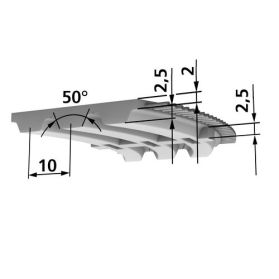

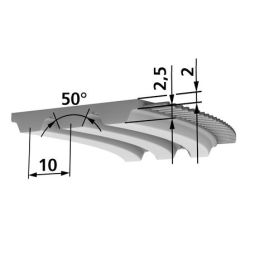

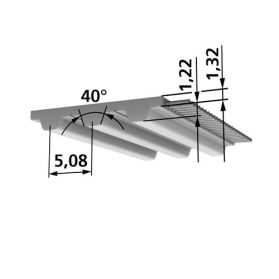

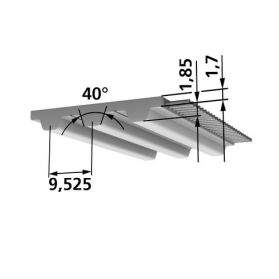

Belts for Power Transmission

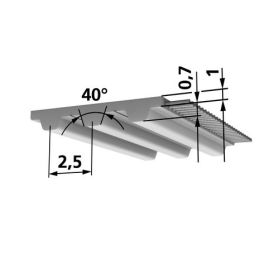

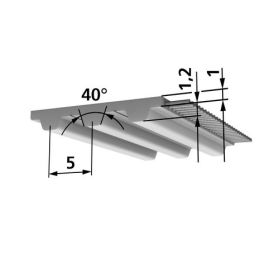

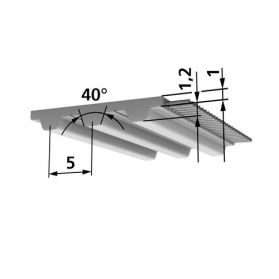

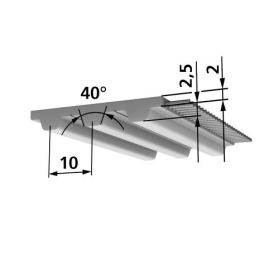

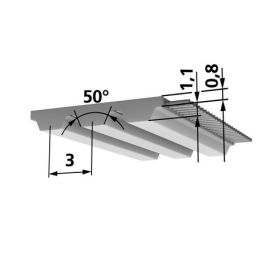

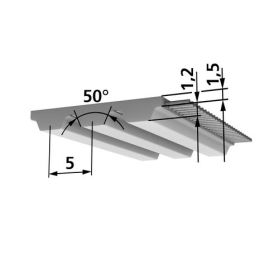

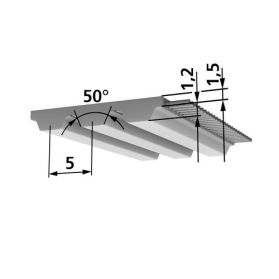

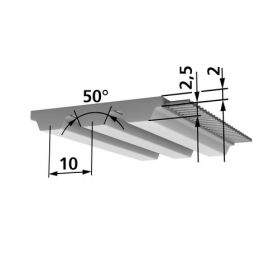

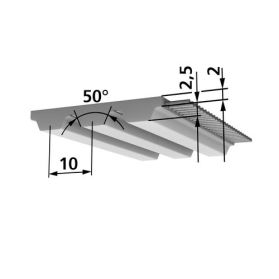

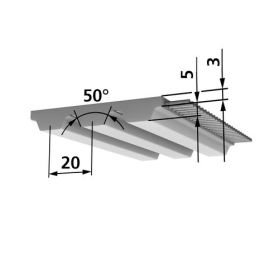

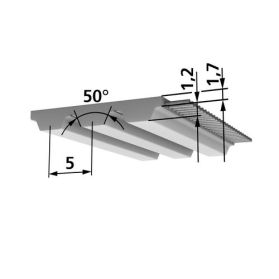

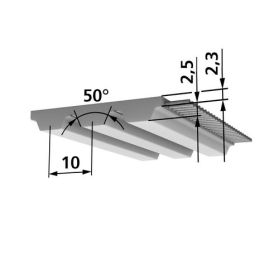

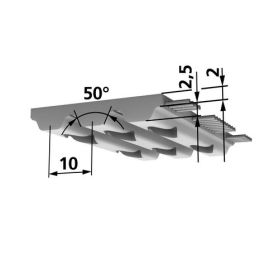

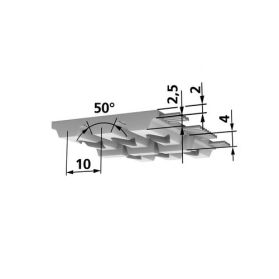

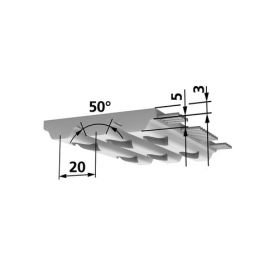

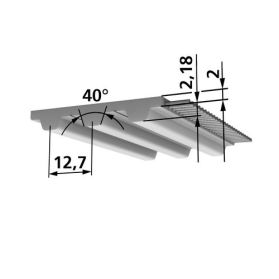

The highest level of performance can be achieved by using tension members with low stretch and a high resistance to reverse bending, selecting the right tooth shape for an optimized force and tension distribution, as well as using the right belt-material-compounding for improved attributes related to the tooth shear strengths. This is needed to ensure a reliable power transmission for high torques and high dynamic stress.

Belts for linear and transport technology

Angst+Pfister’s timing belts meet our customers’ highest demands and can be adapted to any application in accordance with the construction specifications and deployment conditions. A wide variety of materials, special steel, aramid cord designs and diverse coating options are available.

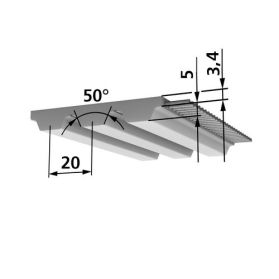

Besides our standard portfolio another addition to maintain the highest flexibility, is the possibility of mechanical finishings. For linear and transport tasks, the high-quality drive elements are also available with weld-on or bolt-on flights. For further assistance, please don't hesitate to get in touch with us.

The belt toothing is in meshing contact with the pulley and in frictional contact with the belt guidance. For this reason, choosing the right contact partners is a crucial task to ensure smooth drive characteristics. To improve the gliding properties and reduce the friction coefficient our PUR belts can be optimized with a standard or even with an antistatic polyamide tissue on the tooth or backside (PAZ & PAR / PAZ-AS & PAR-AS).

The belt backside is in direct contact with the finished or semi-finished product. Certain backings make it possible to ensure synchronous transport and positioning of goods for special machining and processing operations. Whether pockets, contours, slots or holes – we have countless possibilities for precise mechanical reworkments and refinement.